In the vibrant and imaginative world of the toy industry, CNC milling has become an essential technological asset, enabling us to craft toys that combine creativity, safety, and durability. By leveraging the precision and versatility of CNC milling, we can produce components with intricate details and exacting tolerances, meeting the diverse and evolving demands of modern toy designs. Whether it’s manufacturing parts for action figures or creating complex mechanisms for interactive toys, CNC milling seamlessly integrates into our production processes, allowing us to bring innovative and engaging toys to children worldwide and elevate their play experiences.

1. CNC Milling: Precision Fabrication of Toy Vehicle Components

One of the primary applications of CNC milling in the toy industry is the production of components for toy vehicles, such as cars, trucks, and trains. We rely on CNC milling to manufacture crucial parts like axles, wheels, and chassis with high accuracy and consistency, ensuring smooth movement and long – lasting quality in these toys.

Using CNC milling machines, we can create axles with precise diameters and smooth surfaces. For example, in remote – controlled toy cars, the CNC – milled axles are engineered to provide a stable axis of rotation for the wheels, enabling seamless maneuvering and precise control. The wheels produced through CNC milling can feature detailed tread patterns and accurate dimensions, enhancing both the aesthetic appeal and the performance of the toy vehicles. Additionally, the chassis components, often milled from durable materials, are designed with specific mounting points for motors, batteries, and other internal parts. The high – precision machining of these components ensures a secure and well – organized assembly, reducing the risk of parts coming loose during play and increasing the overall durability of the toy vehicles.

2. CNC Milling: Customization of Action Figure Parts

Action figures are cherished for their detailed designs and the ability to be posed in various ways. CNC milling plays a vital role in the customization of action figure parts, allowing us to create unique and highly detailed figures that capture the imagination of collectors and children alike.

We use CNC milling to produce heads, limbs, and accessories for action figures with intricate features. The precision of CNC milling enables us to replicate fine details such as facial expressions, hairstyles, and clothing textures with remarkable accuracy. For instance, the heads of action figures can have realistic facial features, from the shape of the eyes to the contours of the lips, making them look lifelike. The limbs are milled to fit together seamlessly, providing a wide range of motion for different poses. Moreover, CNC – milled accessories like weapons, jewelry, and clothing items can be customized to match the theme and style of the action figure, adding to its overall charm. By offering customized action figure parts through CNC milling, we can meet the diverse preferences of consumers and create collectible toys with high market value.

3. CNC Milling: Production of Toy Building Block Connectors

Toy building blocks are popular for fostering children’s creativity and problem – solving skills. CNC milling is employed to produce the connectors and interlocking parts of building blocks, ensuring a secure and user – friendly connection system.

CNC – milled connectors for building blocks are designed with precise shapes and dimensions. The high – precision machining guarantees that the connectors can withstand repeated assembly and disassembly without losing their grip or getting damaged. For example, in plastic building blocks, the CNC – milled protrusions and sockets are engineered to fit together tightly, allowing children to build stable structures of various shapes and sizes. The smooth surfaces of the CNC – milled connectors also prevent children from getting scratched during play. Additionally, CNC milling enables the creation of different types of connectors, such as angled joints and rotating connectors, expanding the building possibilities and enhancing the educational value of the toy building block sets.

4. CNC Milling: Creation of Interactive Toy Mechanisms

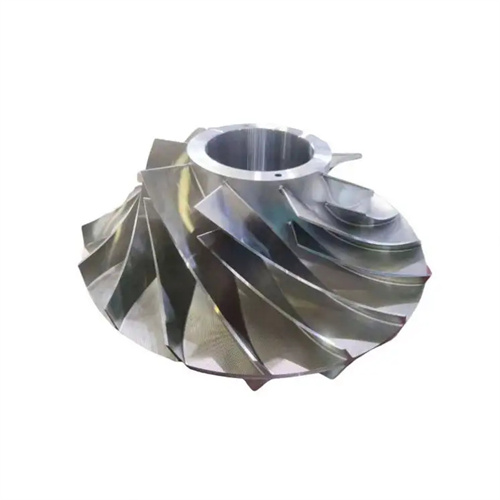

Interactive toys, including robotic toys, musical toys, and electronic learning toys, rely on complex mechanisms to provide engaging play experiences. CNC milling is used to create the internal mechanisms and moving parts of these toys with high precision, ensuring smooth operation and reliable performance.

In robotic toys, CNC – milled components are used in the joints, gears, and drive systems. The high – precision machining of the joints allows for smooth and accurate movement, enabling the robot to perform various actions, from walking and dancing to interacting with its environment. The gears produced through CNC milling have exact tooth profiles, ensuring efficient power transmission and minimizing noise during operation. For musical toys, CNC – milled parts can be used in the sound – producing mechanisms, such as the hammers in toy pianos or the drums in percussion toys. The precise machining of these parts ensures that the toys produce clear and consistent sounds, enhancing the musical play experience for children. The reliability of CNC – milled mechanisms in interactive toys ensures long – lasting enjoyment for young users.

5. CNC Milling: Driving Innovation in High – Tech Toys

As the toy industry continues to embrace technological advancements, CNC milling is at the forefront of driving innovation in high – tech toys. We integrate CNC – milled components with sensors, actuators, and control systems to create advanced toys that can interact with children in new and exciting ways.

For example, in smart toys that respond to voice commands or touch, CNC – milled parts are used in the structural frames and moving components. The precision of CNC milling ensures that these parts fit together perfectly, providing a stable and reliable platform for the integration of electronic components. The high – quality machining also allows for the creation of sleek and modern designs, making the high – tech toys visually appealing. Additionally, CNC – milled parts can be customized to house specific sensors and actuators, enabling the toys to perform a wide range of functions, such as learning, teaching, and entertaining. Through continuous exploration and application of CNC milling in high – tech toys, we can shape the future of the toy industry, creating more intelligent, interactive, and educational toys for children.