Design Service

We are experts in CNC Machining, CNC Turning, CNC Milling and Fasteners of China, our technicians will assist you in developing and designing new machined parts, including material selection, heat treatment options, surface treatment, wear resistance requirements and more.

Shipping Service

CNC Machining Parts located in the coastal city of Xiamen, it has the advantages of sea, land, and air transportation. The air freight speed is fast, which is suitable for transporting precision cnc machining parts; Sea freight is cheap, suitable for transporting large volume and heavy machined parts.

Quality Service

We have a technical team of over 10 people, a frontline operator of 40 people, and a quality inspection team of over 10 people. We can meet all material requirements, delivery time requirements, and outsourcing requirements with quality and quantity assurance.

CNC Machining Parts Manufacturer

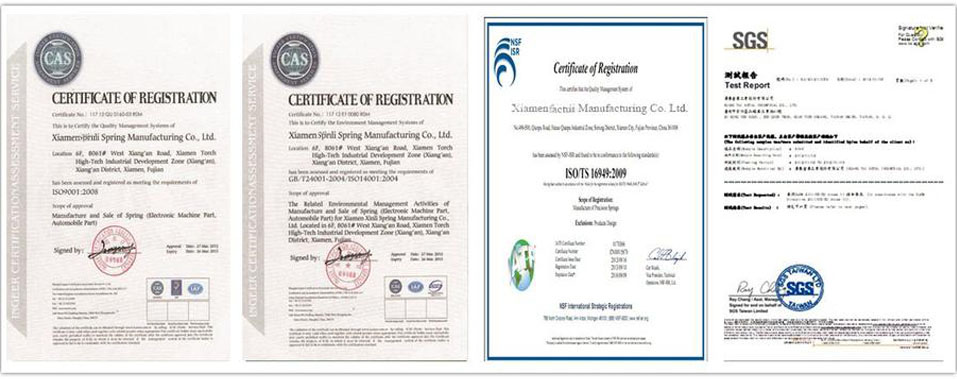

CNC Machining Parts is a company specializing in the processing of CNC machining, CNC turning, CNC milling, fasteners, precision hardware turning parts, cold heading parts, and other related products. With a factory area of over 4000 square meters, we have been committed to the precision hardware machining industry for nearly 20 years, have passed ISO9001 quality certification, and have rich experience in non-standard customization. Equipped with 20 CNC lathes, over 40 automatic lathes, over 20 instrument cars, as well as automatic milling and flattening machines, automatic punching machines, and automatic tapping machines, 2D imaging machines, industrial electron microscopes, and various tooling calipers and gauges.

OUR CAPABILITIES

CNC Machining

CNC machining is a process of high-precision machining of metal or non-metal materials through computer numerical control technology. It can perform cutting, drilling, milling and other operations of complex shapes, and is widely used in industries such as LED lighting, electronic products, electrical products, packaging, etc Our CNC Machining factory focuses on providing customers with high-quality and high-precision metal and plastic processing services. We have advanced CNC machine tools and a professional technical team, which can meet various complex processing needs of customers.

CNC Turning

CNC turning is a process of machining a workpiece by rotating it and using cutting tools. It is mainly used to produce cylindrical or axisymmetric parts, such as shafts, sleeves, threaded parts, etc. CNC turning has the characteristics of high precision and high efficiency, and is widely used in the fields of toys, household appliances, hardware tools, medical equipment, and mechanical manufacturing. Our team consists of a group of experienced engineers and technicians who are proficient in CNC programming, tool selection, cutting parameter adjustment, and other related knowledge.

CNC Milling

CNC milling is a process of machining fixed workpieces through rotating cutting tools, suitable for producing complex geometric parts such as shells, molds, brackets, etc. CNC milling multi axis linkage machining meets the requirements of high precision and complex structures, and is widely used in electrical products, household appliances, medical equipment, and other fields. The main working principle of CNC Milling is to use a rotating cylindrical cutting head and multiple chip groove milling cutters, which move along different axes, to process prismatic parts such as narrow spaces, grooves, outer profiles, etc.

Custom Fasteners

Customized fasteners are connectors such as bolts, nuts, screws, etc. designed and produced according to specific customer needs. We offer a variety of materials, sizes, and surface treatment options to ensure that fasteners meet the strength, corrosion resistance, and aesthetic requirements of different industries, and are widely used in fields such as automotive, construction, and mechanical equipment. Our custom fasteners are customized according to specific needs, specifications, or designs. These fasteners can include various types such as bolts, nuts, washers, threaded fasteners, etc. used to connect, fix, or support various machinery, equipment, or structures.

CNC Machining Shafts

CNC machining shaft parts are high-precision shaft components produced through CNC turning or milling technology, such as drive shafts, spindles, connecting shafts, etc. We can process various complex shapes and sizes of shaft parts according to customer needs, ensuring that they have high precision, high strength, and excellent surface quality, Shafts mainly used in transmission mechanical systems. They can be individual rods or composite rods composed of multiple rods. Shafts play a crucial role in transmitting power and torque in mechanical equipment, typically used to connect two or more rotating components.

CNC Machining Gears

CNC machining gears are high-precision gears produced through CNC technology, including spur gears, helical gears, bevel gears, etc. We use advanced processing equipment and strict quality control to ensure that gears have excellent meshing performance and durability, and are widely used in fields such as automotive transmissions, industrial machinery, and robots. Using CNC machining to produce gears is an efficient method. CNC milling machine tools can precisely perform milling operations according to preset machining programs through computer control, thereby producing gears that meet the complex requirements.

CNC Turning Service

CNC turning uses CNC lathes, which are automated machine tools controlled by programs that process raw materials into semi-finished or finished parts through tool cutting. CNC turning lathes are mainly used for cutting the inner and outer cylindrical surfaces of shaft or disc parts, inner and outer conical surfaces with arbitrary cone angles, complex rotating inner and outer surfaces, and cylindrical and conical threads. They can also perform slotting, drilling, reaming, and boring.

Our CNC Turning automatic lathe can achieve fully automated processing, automatic feeding, processing, and even finished products, which can greatly improve production efficiency and reduce costs. Our CNC Turning can achieve machining accuracy at the micrometer level, meeting the needs of high-precision manufacturing.

CNC Machining Secondary Services

We also provide CNC Machining secondary processing services, mainly for further processing of pre formed workpieces to meet specific design or functional requirements. Mainly including tapping and tapping, milling, grinding, drilling, and reaming. Tapping and threading are mainly used in fasteners such as screws and nuts. Milling is the use of a rotating milling cutter to cut flat, grooved, and other shapes on the workpiece; Grinding is the process of precision machining the surface of a workpiece using a grinding tool to improve its surface quality; Turning is the process of machining the inner and outer surfaces of workpieces through a lathe; Drilling is the process of drilling holes on a workpiece using a drill bit.

Manufacture

Machining Of Cast Aluminum Alloy Inner Tapered Sleeve

Vertical Machining Of Inner And Outer Cones In Cast Iron

Machining Of Cast Iron Porous Bracket

Machining Of Cast Iron Forks

Machining Of Shafts Rods And Spindles

Broaching Of Keyway In Inner Hole Of Long Shaft

Grinding Workpieces On A Lathe

OUR CERTIFICATES