In the rapidly advancing and highly competitive field of electrical products, CNC milling has emerged as an indispensable technology, empowering us to manufacture components and devices with exceptional precision, reliability, and functionality. By harnessing the capabilities of CNC milling, we can fabricate parts with intricate geometries and tight tolerances, meeting the diverse and stringent requirements of modern electrical applications. Whether it’s producing components for electric motors or creating enclosures for electronic devices, CNC milling seamlessly integrates into our production processes, enabling us to overcome technical challenges, enhance product performance, and drive innovation in the electrical product industry.

1. CNC Milling: Precision Fabrication of Electric Motor Components

One of the primary applications of CNC milling in electrical products is the production of components for electric motors. We rely on CNC milling to manufacture crucial parts such as stators, rotors, and end caps with high accuracy and consistency, ensuring the efficient and reliable operation of electric motors.

Using CNC milling machines, we can create intricate slot patterns on stator laminations with extreme precision. These slots are essential for housing the motor windings, and the accuracy of the milling process ensures optimal magnetic field distribution, reducing energy losses and enhancing the motor’s overall efficiency. For rotors, CNC milling allows us to shape the cores with precise dimensions, ensuring a perfect fit within the stator and minimizing air gaps. This not only improves the motor’s performance but also reduces vibrations and noise during operation. Additionally, CNC – milled end caps provide a secure and precise mounting for the motor bearings, further contributing to the motor’s reliability and longevity. By using CNC milling for these components, we can significantly enhance the performance and durability of electric motors, making them suitable for a wide range of applications from household appliances to industrial machinery.

2. CNC Milling: Creation of Electrical Device Enclosures

CNC milling plays a vital role in the production of enclosures for electrical devices, which protect the internal components and contribute to the overall aesthetics and functionality of the products. We use CNC milling to shape enclosures from materials such as aluminum, stainless steel, and engineering plastics according to detailed design specifications.

The precision of CNC milling enables us to incorporate complex features into the enclosures, including ventilation holes, cable entry points, and mounting bosses. For example, in the case of electronic control panels, CNC – milled aluminum enclosures can be crafted with precisely positioned ventilation holes to ensure proper heat dissipation, preventing the internal components from overheating. The ability to mill intricate patterns and logos directly onto the enclosure surface also adds a touch of customization and brand identity. Moreover, the accurate machining ensures that the enclosure parts fit together seamlessly, providing excellent protection against dust, moisture, and electromagnetic interference. The high – quality enclosures produced through CNC milling not only enhance the performance and lifespan of the electrical devices but also improve their visual appeal, making them more attractive to consumers.

3. CNC Milling: Production of Electrical Connector Components

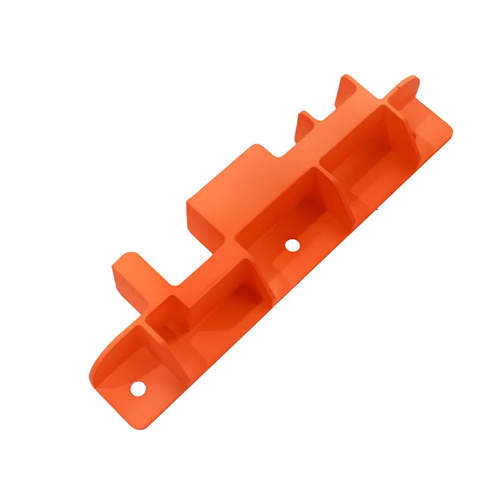

Electrical connectors are essential for establishing reliable electrical connections in electrical products, and CNC milling enables their precise fabrication. We employ CNC milling processes to manufacture connector components such as housings, pins, and sockets with accurate shapes and tight tolerances.

For connector housings, CNC milling allows us to create complex geometries with precise internal cavities and external features. The accurate machining ensures a perfect fit for the internal electrical contacts and provides mechanical protection for the connectors. In the production of pins and sockets, CNC milling enables the creation of precise contact surfaces, reducing electrical resistance and ensuring stable signal transmission. The ability to mill fine details such as locking mechanisms and alignment features into the connector components further enhances their reliability and ease of use. Whether it’s for consumer electronics or high – end industrial electrical systems, the precision of CNC – milled electrical connector components is crucial for ensuring the integrity and performance of electrical connections.

4. CNC Milling: Customization for Electrical Equipment Assemblies

CNC milling offers us the flexibility to customize various components for electrical equipment assemblies, catering to the specific requirements of different projects and applications. We can use CNC milling to produce custom – made brackets, mounts, and frames that are tailored to the unique installation needs of electrical systems.

For large – scale electrical control cabinets, CNC – milled brackets can be designed and fabricated to securely hold circuit breakers, relays, and other electrical components in place. These custom brackets can be milled with specific hole patterns, slots, and shapes to match the mounting points of the components, facilitating easy installation and maintenance. In addition, CNC – milled frames can be created to provide structural support for complex electrical assemblies, ensuring the stability and alignment of the components. The ability to customize components through CNC milling allows us to offer personalized solutions for our customers, enhancing the adaptability and functionality of our electrical products in diverse settings.

5. CNC Milling: Driving Innovation in Smart Electrical Products

As the electrical product industry continues to embrace the era of intelligence and automation, CNC milling is at the forefront of driving innovation in smart electrical products. We integrate CNC – milled components with sensors, actuators, and control systems to create advanced electrical devices that can adapt to changing environments and user needs.

In smart home appliances, CNC – milled components can be used in the adjustable parts that are controlled by sensors detecting factors such as temperature, humidity, and occupancy. The precision of CNC milling ensures that the moving parts, such as adjustable vents and rotating panels, operate smoothly and accurately, enabling the appliances to adjust their settings automatically for optimal performance and energy efficiency. In addition, in the enclosures of smart electrical controllers, CNC – milled parts provide a robust and compact housing for the electronic components, protecting them from external interference and ensuring reliable operation. Through continuous exploration and application of CNC milling in smart electrical products, we can drive the development of more intelligent, user – friendly, and energy – efficient electrical solutions, shaping the future of the electrical product industry.