In the construction industry, where precision, durability, and safety are non – negotiable, custom fasteners have emerged as indispensable components in our projects. These tailor – made fasteners allow us to address the unique requirements of different construction applications, from ensuring the structural integrity of buildings to facilitating the assembly of complex construction machinery. By leveraging custom fasteners, we can enhance the quality and reliability of our construction projects, meet stringent safety standards, and deliver structures that stand the test of time.

1. Custom Fasteners: Ensuring Structural Integrity in Building Frames

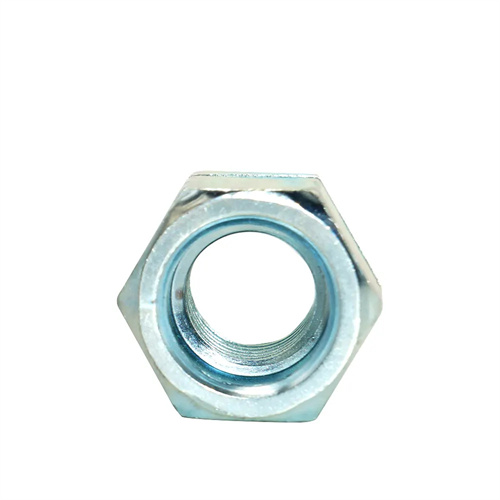

One of the primary applications of custom fasteners in the construction industry is to ensure the structural integrity of building frames. We rely on custom – designed bolts, nuts, and rivets to connect steel beams, columns, and other structural components, creating a robust and stable framework for buildings.

For high – rise buildings, custom – made high – strength bolts are used to join steel beams at critical load – bearing points. These bolts are engineered with specific diameters, lengths, and thread pitches to withstand immense forces, such as gravity, wind, and seismic loads. The nuts are custom – designed to provide a secure and tight fit, preventing any loosening over time. In addition, custom – engineered rivets are often employed in the assembly of metal trusses. These rivets are customized in size and shape to ensure a strong and permanent connection between the truss members, enhancing the overall stability of the roof structure. By using these custom fasteners, we can ensure that building frames can safely support the weight of the building and its occupants, as well as resist external forces.

2. Custom Fasteners: Facilitating the Assembly of Construction Machinery

Construction machinery, such as cranes, excavators, and bulldozers, requires reliable fasteners for its assembly and maintenance. We use custom – made pins, bushings, and screws to ensure the smooth operation and durability of these machines.

Custom – designed pins are used to connect the various moving parts of cranes, such as the boom sections and the lifting mechanism. These pins are engineered to have precise diameters and lengths to fit the corresponding holes in the machine components, allowing for smooth and controlled movement. The bushings, which are custom – made to fit around the pins, reduce friction and wear, extending the lifespan of the moving parts. In excavators, custom – made screws are used to secure the hydraulic cylinders and other critical components. These screws are designed to withstand the high pressures and vibrations generated during operation, ensuring the reliable performance of the machine. By using custom fasteners in construction machinery, we can minimize downtime due to breakdowns and improve the efficiency of construction projects.

3. Custom Fasteners: Securing Building Envelopes

Building envelopes, including walls, roofs, and windows, need to be securely fastened to protect the interior of buildings from the elements. We use custom – designed clips, anchors, and fasteners to ensure the proper installation and sealing of these components.

For exterior walls, custom – made wall clips are used to attach insulation boards, siding, and other cladding materials. These clips are designed to fit the specific thickness and shape of the materials, providing a secure and weather – resistant connection. In roofing systems, custom – engineered roof anchors are used to secure roof tiles, shingles, or metal sheets. These anchors are customized to withstand wind uplift forces and other environmental factors, preventing the roofing materials from being blown off. For windows and doors, custom – made fasteners are used to ensure a tight seal, preventing air and water infiltration. By using these custom fasteners, we can improve the energy efficiency of buildings and protect the interior from damage caused by moisture and extreme weather conditions.

4. Custom Fasteners: Reinforcing Masonry and Concrete Structures

Masonry and concrete structures often require additional reinforcement, and custom fasteners offer effective solutions for this purpose. We use custom – designed anchors, bolts, and ties to strengthen these structures and improve their load – bearing capacity.

In masonry walls, custom – made masonry anchors are used to connect the wall to the building frame or other structural elements. These anchors are engineered to penetrate the masonry units and provide a secure connection, enhancing the stability of the wall. In concrete structures, custom – designed expansion bolts are used to anchor various fixtures, such as handrails, signage, and mechanical equipment. These bolts are customized to fit the specific requirements of the application, ensuring a strong and reliable connection. Additionally, custom – made concrete ties are used to reinforce concrete slabs and walls, preventing cracking and improving the overall structural performance. By using custom fasteners for reinforcement, we can ensure the long – term durability and safety of masonry and concrete structures.

5. Custom Fasteners: Driving Innovation in Sustainable Construction

As the construction industry increasingly focuses on sustainability, custom fasteners are playing a significant role in promoting eco – friendly practices. We are developing custom fasteners made from recycled materials, as well as those designed for easy disassembly and recycling at the end of a building’s life cycle.

Custom – made fasteners made from recycled steel or aluminum are being used in construction projects to reduce the demand for virgin materials. These fasteners are engineered to meet the same performance standards as traditional fasteners while contributing to a more circular economy. In addition, custom – designed fasteners with a modular and reversible design are being developed to facilitate the disassembly of buildings. These fasteners can be easily removed without causing damage to the surrounding materials, allowing for the reuse of building components and reducing construction waste. By driving innovation in custom fasteners for sustainable construction, we can make a positive impact on the environment and build more sustainable communities.