In the dynamic and ever – evolving construction industry, where precision, durability, and innovation are key to success, CNC turning has emerged as an invaluable technology. It empowers us to manufacture components with exceptional accuracy and consistency, meeting the diverse and stringent requirements of modern construction projects. Whether it’s fabricating parts for heavy construction machinery or creating intricate architectural elements, CNC turning seamlessly integrates into our production processes, enabling us to enhance the quality, efficiency, and sustainability of our constructions. By leveraging the capabilities of CNC turning, we can overcome technical challenges, drive innovation, and build structures that stand the test of time.

1. CNC Turning: Precision Fabrication of Construction Machinery Axles

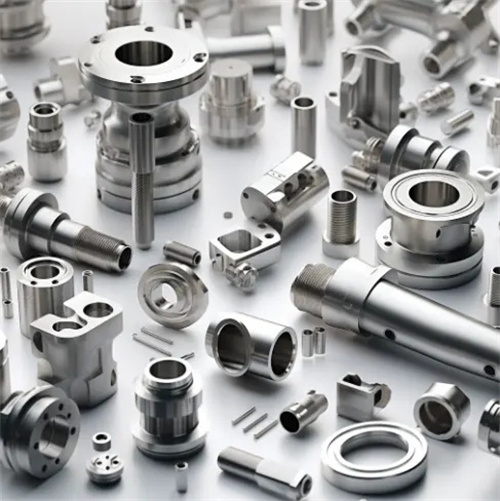

One of the primary applications of CNC turning in the construction industry is the production of axles for construction machinery, such as excavators, cranes, and loaders. We rely on CNC turning to manufacture these critical components with high precision, as the performance and safety of the machinery depend on the quality of their axles.

Using CNC turning machines, we can create axles from robust materials like alloy steel or high – strength stainless steel with precise diameters, lengths, and surface finishes. The high – speed rotation and advanced cutting tools of CNC turning allow us to achieve extremely tight tolerances, ensuring a perfect fit for bearings, wheels, and other moving parts. For example, in a large – scale crane, the main axle needs to withstand heavy loads and continuous stress during operation. The precision machining of CNC turning ensures that the axle has uniform strength and minimal dimensional deviation,reducing the risk of breakage and enhancing the overall stability of the crane. Additionally, the smooth surface finish of the CNC – turned axles minimizes friction, extending the lifespan of the bearings and reducing maintenance costs.

2. CNC Turning: Creation of Structural Steel Rods and Bolts

In construction projects, structural steel rods and bolts play a crucial role in ensuring the integrity and stability of buildings and bridges. CNC turning is employed to produce these components with high accuracy and reliability, enabling secure connections between different structural elements.

We use CNC turning to shape steel rods and bolts from various grades of steel, tailoring their dimensions to meet specific design requirements. The precision of CNC turning allows us to create threads with exact pitches and diameters, ensuring a tight and secure fit when assembling structural components. For example, in the construction of a skyscraper, the CNC – turned bolts used to connect steel beams need to have consistent quality and strength. The high – quality machining ensures that the bolts can withstand the immense forces exerted on the structure, providing long – term durability. Moreover, CNC – turned steel rods can be customized with specific end – shapes, such as tapered ends or threaded ends, to facilitate their installation in different structural applications.

3. CNC Turning: Production of Architectural Ornamental Elements

Architectural ornamentation adds aesthetic appeal and character to buildings, and CNC turning offers us the ability to create intricate and detailed ornamental elements with high precision. We use CNC turning to manufacture components such as balusters, columns, and decorative spindles from materials like metal, wood, or composite materials.

For metal balusters used in balconies or staircases, CNC turning enables us to create smooth, symmetrical shapes with precise profiles. The ability to control the diameter, length, and surface texture of the balusters allows for endless design possibilities, from classic to modern styles. In the case of wooden columns, CNC – turned components can be crafted with intricate carvings and patterns, enhancing the visual appeal of the building’s facade. The high – quality finish achieved through CNC turning ensures that these ornamental elements not only look beautiful but also have excellent durability, resisting wear and tear over time.

4. CNC Turning: Customization of Plumbing and Piping Fittings

In the plumbing and piping systems of buildings, fittings need to be precisely manufactured to ensure leak – free connections and efficient fluid flow. CNC turning offers us the flexibility to customize these fittings according to the specific requirements of different plumbing projects.

We can design and manufacture custom – made plumbing and piping fittings through CNC turning from materials like copper, PVC, or stainless steel. The precision of CNC turning allows for the creation of fittings with accurate internal and external diameters, as well as precise thread profiles. For example, in a complex industrial plumbing system, the CNC – turned elbows and tees need to have exact angles and dimensions to ensure proper alignment and connection of the pipes. The ability to customize these fittings also enables us to adapt to unique building layouts and design requirements, ensuring the optimal performance of the plumbing system.

5. CNC Turning: Driving Innovation in Sustainable Construction

As the construction industry increasingly focuses on sustainability, CNC turning is at the forefront of driving innovation in creating eco – friendly construction solutions. We leverage CNC turning to produce components that optimize material usage, reduce waste, and enhance the recyclability of construction materials.

For example, CNC – turned components can be designed to use the minimum amount of material without sacrificing strength and functionality. By precisely machining parts to the required dimensions, we can minimize material waste during production. In addition, CNC – turned parts made from recyclable materials, such as aluminum or certain types of plastics, can be easily disassembled and recycled at the end of a building’s life cycle. Moreover, CNC turning enables the production of components with complex geometries that can be used in innovative sustainable construction techniques, such as modular building systems. Through continuous exploration and application of CNC turning in sustainable construction, we can contribute to a greener and more sustainable future for the construction industry.