In the competitive and innovation – driven sports goods industry, CNC machining has emerged as an indispensable technology, enabling us to create high – quality, high – performance sports products that meet the diverse needs of athletes and sports enthusiasts. By leveraging the precision, versatility, and consistency of CNC machining, we can fabricate components with intricate designs and tight tolerances, ensuring optimal functionality and durability in our sports goods. Whether it’s manufacturing parts for fitness equipment or creating custom – made components for sports gear, CNC machining seamlessly integrates into our production processes, allowing us to overcome technical challenges, enhance user experiences, and drive the advancement of the sports goods industry.

1. CNC Machining: Precision Fabrication of Fitness Equipment Components

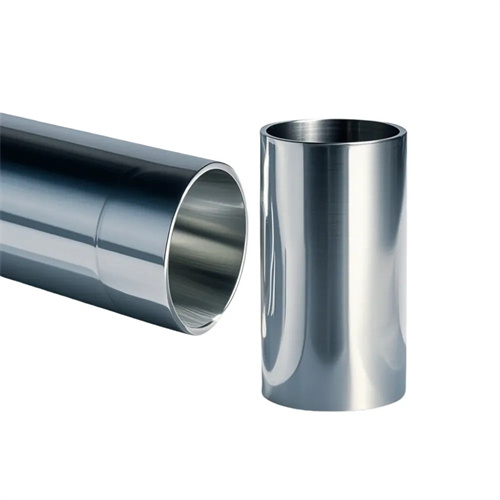

One of the primary applications of CNC machining in sports goods is the production of components for fitness equipment, such as treadmills, exercise bikes, and weightlifting machines. We rely on CNC machining to manufacture critical parts like shafts, pulleys, and gears with exceptional accuracy and consistency, ensuring the smooth and reliable operation of these fitness devices.

CNC turning and milling processes enable us to create shafts with precise diameters and smooth surfaces, which are essential for reducing friction and minimizing wear in the moving parts of fitness equipment. For example, in a treadmill, the CNC – machined shaft that supports the rotation of the running belt ensures a stable and consistent movement, preventing belt slippage and providing users with a comfortable running experience. Pulleys and gears produced through CNC machining have exacting tooth profiles and dimensions, allowing for efficient power transmission and accurate resistance adjustment in exercise bikes and weightlifting machines. The high – precision machining of these components not only enhances the performance of the fitness equipment but also extends its lifespan, reducing the need for frequent maintenance and replacement.

2. CNC Machining: Customization of Sports Equipment Frames

Many sports, such as cycling, skiing, and tennis, require equipment frames that are lightweight, strong, and tailored to the specific needs of athletes. CNC machining plays a crucial role in the customization of these frames, allowing us to create unique and high – performance structures from materials like aluminum alloy, carbon fiber, and titanium.

We use CNC machining to precisely cut, shape, and drill holes in frame components, ensuring a perfect fit for other parts and optimizing the overall strength – to – weight ratio. In cycling, for instance, CNC – machined carbon fiber bike frames can be designed with complex geometries to enhance aerodynamics and power transfer, giving cyclists a competitive edge. The precision of CNC machining also enables the creation of intricate designs and patterns on the frames, adding to the aesthetic appeal of the sports equipment. By offering customized frames through CNC machining, we can meet the individual requirements of athletes, improving their performance and comfort during sports activities.

3. CNC Machining: Production of Sports Ball Components

Sports balls, including basketballs, footballs, and tennis balls, require components that are precisely manufactured to ensure consistent performance and playability. CNC machining is used to produce parts such as valve stems, bladder molds, and outer cover molds with high precision and repeatability.

For valve stems, CNC machining ensures that the dimensions are accurate, allowing for a secure and air – tight connection to the ball’s bladder. The high – precision machining of bladder molds results in uniform bladder shapes, which is essential for maintaining the ball’s roundness and bounce. In the production of outer cover molds, CNC machining enables the creation of detailed textures and patterns, enhancing the grip and control of the ball. Whether it’s for professional sports competitions or recreational use, the consistent quality of CNC – machined sports ball components contributes to a better playing experience for athletes and enthusiasts alike.

4. CNC Machining: Creation of Sports Protective Gear Parts

Sports protective gear, such as helmets, pads, and guards, is designed to safeguard athletes from injuries during intense physical activities. CNC machining is employed to produce parts of these protective gears with high precision and reliability, ensuring both safety and comfort.

In helmet production, CNC machining is used to create the inner liners and outer shells with exacting specifications. The precision of CNC machining allows for the incorporation of ventilation holes and channels in the helmet shells, improving air circulation and reducing heat buildup. For pads and guards, CNC – machined components can be customized to fit different body parts, providing a snug and secure fit. The high – quality materials and precise machining of these parts ensure that the protective gear can effectively absorb impacts and distribute forces, minimizing the risk of injuries. By using CNC machining in the production of sports protective gear, we can enhance the safety and confidence of athletes during their sports endeavors.

5. CNC Machining: Driving Innovation in High – Tech Sports Equipment

As the sports goods industry continues to embrace technological advancements, CNC machining is at the forefront of driving innovation in high – tech sports equipment. We integrate CNC – machined components with sensors, actuators, and smart control systems to create advanced sports products that can adapt to different conditions and enhance athletes’ performance.

For example, in smart running shoes, CNC – machined parts can be used in the adjustable support structures that are controlled by sensors detecting foot pressure and movement. The precision of CNC machining ensures smooth and reliable adjustment, providing personalized support and cushioning for runners. In robotic sports training devices, CNC – machined components enable precise and controlled movements, simulating real – life sports scenarios for effective training. The high – precision and reliability of CNC – machined components in high – tech sports equipment are essential for seamless integration with other smart technologies, driving the development of more intelligent, efficient, and performance – enhancing sports products. Through continuous exploration and application of CNC machining in high – tech sports equipment, we can shape the future of sports performance and training.