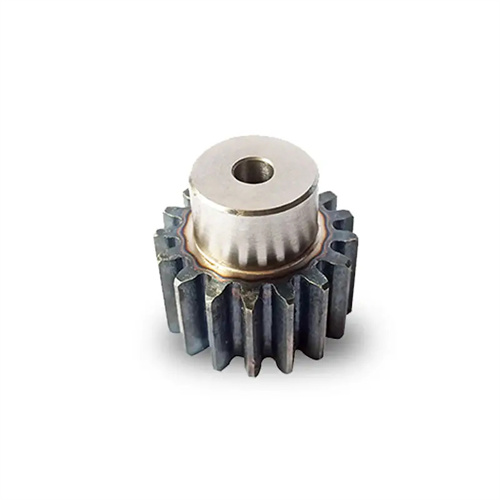

In the rapidly evolving landscape of LED lighting, CNC machining gears have emerged as a crucial component, enabling us to elevate the performance, functionality, and reliability of our lighting products. By leveraging the precision and consistency of CNC machining technology, we can produce gears that are tailored to the specific requirements of LED lighting systems, whether it’s for facilitating smooth mechanical movements in adjustable fixtures or ensuring accurate control in automated lighting setups. These gears have seamlessly integrated into our manufacturing processes, allowing us to overcome engineering challenges and create innovative LED lighting solutions that meet the diverse needs of modern applications, from commercial spaces to residential environments.

1. CNC Machining Gears: Facilitating Smooth Adjustment in LED Spotlight Fixtures

One of the primary applications of CNC machining gears in LED lighting is in spotlight fixtures, where the ability to adjust the angle of the light precisely is essential. We utilize CNC machining gears in the adjustment mechanisms of LED spotlights to ensure smooth, consistent, and accurate movement of the light – emitting components.

For commercial settings such as art galleries and museums, LED spotlights need to be adjustable to highlight exhibits from various angles. CNC – machined gears are integrated into the hinge and rotation systems of these spotlights. The high precision of CNC machining ensures that each tooth of the gear is cut with exact dimensions, providing a smooth and seamless rotation when the user adjusts the spotlight’s angle. This precision not only allows for fine – tuning of the light direction but also ensures that the spotlight remains stable in the set position, preventing any unwanted wobbling. In addition, the durability of CNC – machined gears means that the adjustment mechanism can withstand frequent use without wear and tear, maintaining the spotlight’s performance over a long lifespan.

2. CNC Machining Gears: Enabling Precise Dimming Control in LED Panels

LED panels often require precise dimming control to create the desired lighting ambiance, and CNC machining gears play a vital role in this aspect. We incorporate CNC – machined gears into the dimming mechanisms of LED panels, working in tandem with motors and control systems to achieve accurate and smooth dimming.

The gears, produced through CNC machining, transfer the rotational motion from the motor to the dimming components with high precision. The tight tolerances achieved during the CNC machining process ensure that the gear teeth mesh perfectly, minimizing backlash and ensuring that the dimming control is responsive and consistent. Whether it’s for adjusting the brightness of LED panels in an office to reduce eye strain or creating a soft, ambient glow in a hotel lobby, the CNC – machined gears enable us to achieve precise dimming levels. Moreover, the reliability of these gears ensures that the dimming system operates smoothly over time, without the risk of gear failure affecting the lighting performance.

3. CNC Machining Gears: Supporting the Movement of LED Display Screens

In large – scale LED display installations, such as those in stadiums, concert halls, and public squares, the smooth movement of display screens is crucial for creating dynamic visual effects. CNC machining gears are used in the mechanical systems that drive the movement of these LED display screens.

We design and manufacture CNC – machined gears to fit the specific requirements of LED display screen movement, whether it’s for rotating, tilting, or sliding the screens. The high – quality steel or other suitable materials used in CNC – machined gears, combined with the precision of the machining process, allows for the transmission of high torque without deformation. This is essential when moving large and heavy LED display screens. The accurate tooth profiles of the CNC – machined gears ensure that the movement is synchronized and stable, preventing any jerky motions that could disrupt the visual display. As a result, we can create seamless and captivating visual experiences for audiences with the help of these reliable CNC – machined gears.

4. CNC Machining Gears: Enhancing the Performance of LED – Powered Robotic Lighting Systems

With the rise of intelligent lighting solutions, LED – powered robotic lighting systems are becoming more popular. CNC machining gears are integral to the operation of these systems, enabling precise and coordinated movement of the robotic arms that hold the LED lights.

In robotic lighting setups used for stage performances or architectural lighting displays, CNC – machined gears are installed in the joints of the robotic arms. These gears allow for smooth and accurate rotation, enabling the robotic arms to position the LED lights precisely as per the programmed movements. The high precision of CNC machining ensures that the gears can work in harmony with sensors and control systems, responding quickly to commands for changes in light position and angle. The durability of CNC – machined gears also ensures that the robotic lighting systems can withstand continuous operation over extended periods, making them reliable for demanding applications where consistent performance is key.

5. CNC Machining Gears: Driving Innovation in LED Lighting System Integration

As the LED lighting industry continues to evolve towards more integrated and intelligent systems, CNC machining gears are at the forefront of driving innovation. Their precision and adaptability inspire us to explore new ways of integrating different components and creating more advanced LED lighting solutions.

We are researching and developing new LED lighting systems that combine CNC – machined gears with smart technologies such as artificial intelligence and the Internet of Things (IoT). For example, in future – generation smart buildings, LED lighting systems could use CNC – machined gears in adjustable fixtures that are controlled by sensors and algorithms. These gears would enable the lights to automatically adjust their angles and brightness based on factors like occupancy, natural light levels, and user preferences. The high – quality and precisely – made CNC – machined gears would ensure the smooth operation of these intelligent adjustment mechanisms. Through continuous exploration and application of CNC machining gears in LED lighting system integration, we can drive the industry towards a more energy – efficient, user – friendly, and innovative future.