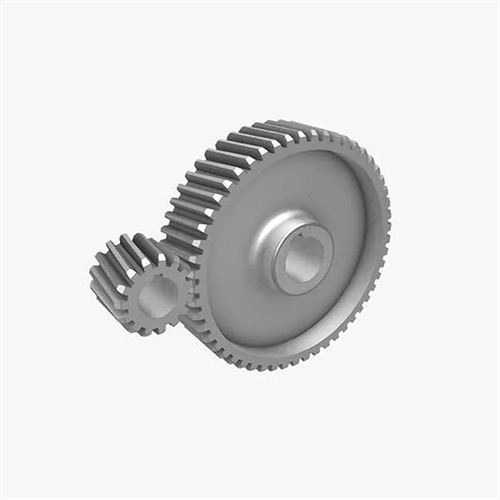

Machining the production of spur gears is an important and precise manufacturing process. Straight cylindrical gears are widely used in various mechanical transmission systems, such as machine tools, automotive transmissions, etc. Firstly, the selection of materials is commonly used, including medium carbon steel (such as 45 steel) and alloy steel (such as 20CrMnTi), which are determined based on specific usage requirements and working conditions. The preparation of raw materials is generally carried out through forging, casting, or bar cutting. Forging can improve the fiber structure of materials and increase the strength of gears; Casting is suitable for production with complex shapes and large batches.

In the tooth profile machining process, the main methods include:

Gear hobbing: Using a gear hobbing machine and a hob, machining is carried out according to the principle of generative method. The production efficiency of gear hobbing is high and suitable for large-scale production.

Gear shaping: Cutting the tooth shape through the up and down reciprocating motion of the gear shaping machine and the gear shaping cutter. Gear shaping is suitable for machining internal gears and multiple gears.

During the machining process, it is necessary to strictly control the relative motion between the cutting tool and the workpiece to ensure the accuracy of the tooth profile and the uniformity of the tooth pitch. For example, in the machining of high-precision spur cylindrical gears, multiple cutting and micro feed are used to reduce errors. In order to improve the surface hardness and wear resistance of gears, heat treatment is usually carried out, such as carburizing quenching, high-frequency quenching, etc. Subsequently, precision machining processes such as gear shaving and honing may also be carried out to further improve the accuracy and smoothness of the tooth surface. Quality inspection is an essential step, and equipment such as gear measuring instruments are used to detect various parameters of gears, such as modulus, number of teeth, tooth profile deviation, tooth orientation deviation, etc.

In the transmission system of machine tools, the accuracy of spur gears directly affects the machining accuracy and working stability of the machine tool. So in the machining production process, every step must be carefully operated and strictly controlled.

In summary, the production of spur gears through machining requires comprehensive consideration of various factors such as materials, processes, equipment, and quality control, in order to produce high-quality gears that meet different application requirements.

Using CNC machining to produce gears is a high-precision and efficient process. The following are the main steps in producing gears:

Design:

Firstly, use CAD (computer-aided design) software to draw the geometric shape of gears. This includes determining key parameters such as number of teeth, pressure angle, modulus, and tooth profile curve. After designing a CAD model, it is necessary to convert it into a machining program that can be recognized by CNC machine tools. This usually involves importing CAD files into CAM (computer-aided manufacturing) software and generating G or M codes.

Material selection:

Select appropriate materials based on the usage and performance requirements of gears. Common metal materials such as steel, stainless steel, aluminum, etc. can be used in the manufacturing of gears.

Programming:

In CAM software, create detailed machining programs based on CAD models. This includes defining parameters such as cutting tools, cutting paths, cutting speeds, feed rates, etc. For gear machining, it may be necessary to use specialized gear cutting tools, such as hobs, gear cutters, etc., and set corresponding cutting parameters.

Set up CNC machine tool:

Fix the selected material (usually cylindrical or block shaped) on the workbench of CNC machine tools.

According to the machining program, install and adjust cutting tools to ensure they can perform cutting operations correctly.

Processing:

Start the CNC machine tool and begin the machining process. The machine tool will automatically cut according to the machining program, gradually processing the material into the shape of gears.

During the machining process, CNC machine tools continuously monitor the position and status of cutting tools to ensure machining accuracy and quality.

Post processing:

After processing, perform necessary post-treatment on the gears, such as removing burrs, heat treatment (such as carburizing to improve hardness and wear resistance), coating, etc. Conduct quality inspection on gears, including size measurement, accuracy testing, surface quality inspection, etc., to ensure that they meet design requirements.

In the dynamic landscape of gear manufacturing, we’ve harnessed the power of CNC machining to revolutionize the production of cylindrical spur gears. These fundamental components are the backbone of countless mechanical systems, and our meticulous approach to CNC machining ensures that each cylindrical spur gear we craft combines unrivaled precision, durability, and performance.

Our journey begins with in – depth collaboration and design. We work closely with clients, whether they’re from the automotive, aerospace, or industrial sectors, to understand their unique requirements for cylindrical spur gears. Using advanced computer – aided design (CAD) software, we translate these needs into highly detailed 3D models. Every aspect of the gear, from the number of teeth and pitch diameter to the face width and tooth profile, is carefully calculated and refined. These digital blueprints serve as the foundation for the entire manufacturing process, allowing us to simulate and optimize the gear’s performance before any material is touched.

Once the design is finalized, material selection becomes our next crucial step. We know that the choice of material can significantly impact the gear’s lifespan and functionality. For most applications, we source high – quality alloy steels, renowned for their strength and wear – resistance. However, depending on specific requirements, we can also work with other materials like aluminum for lightweight applications or stainless steel for enhanced corrosion resistance. After selecting the ideal material, we prepare it by cutting the raw stock to the appropriate size and ensuring its surface is free from any imperfections that could affect the machining process.

Setting up the CNC machine is a task that demands our utmost attention to detail. We carefully install the necessary cutting tools, such as hobs and end mills, into the machine’s tool changer, ensuring they are properly aligned and balanced. The prepared raw material is then securely mounted on the machine’s workholding device, like a chuck or collet, to prevent any movement during the machining operations. We also calibrate the machine’s axes to establish precise zero points, which is essential for maintaining the accuracy of the gear’s dimensions throughout production.

With the machine set up, the actual CNC machining process commences. Cylindrical spur gear manufacturing typically involves a combination of operations. Hobbing is one of the primary processes we use, where a hob tool, which has a similar shape to the gear’s teeth, cuts the tooth profile into the rotating workpiece. This process is highly precise, allowing us to create teeth with consistent spacing and accurate angles. In addition to hobbing, we may perform turning operations to shape the gear’s outer diameter and bore, ensuring it meets the required size specifications. Drilling and tapping operations are also carried out when necessary, for example, to create holes for keyways or mounting bolts.

Quality control is an integral part of our manufacturing process, and we implement rigorous checks at every stage. After the machining operations are complete, we use high – precision measuring instruments, such as coordinate measuring machines (CMMs), to verify the gear’s dimensions. We measure the tooth profile, pitch, and other critical parameters to ensure they fall within the specified tolerances. Surface finish is also carefully inspected, as a smooth surface reduces friction and wear, enhancing the gear’s performance and lifespan. Additionally, we conduct non – destructive tests, like magnetic particle inspection, to detect any internal flaws or defects that could compromise the gear’s integrity.

If the cylindrical spur gear passes all our quality inspections, we move on to the post – machining finishing stage. This can include heat treatment processes, such as carburizing and quenching, to increase the gear’s hardness and strength. We may also apply surface coatings, like phosphate or nitride coatings, to improve wear resistance and reduce friction. Finally, we clean and deburr the gear, ensuring it is ready for assembly.

In conclusion, our process of manufacturing cylindrical spur gears with CNC machining is a harmonious blend of advanced technology, expert craftsmanship, and stringent quality control. By following these meticulous steps, we are able to produce gears that not only meet but exceed our clients’ expectations, providing them with reliable components that drive the success of their mechanical systems.