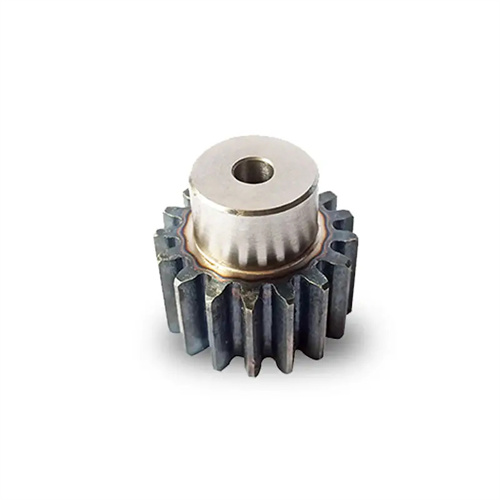

Machining the production of steel spur gears is a precise and critical manufacturing process. Steel spur gears play an important transmission role in many mechanical devices, such as industrial machinery, automotive transmissions, etc. Firstly, in terms of materials, high-quality carbon structural steel (such as 45 steel) or alloy structural steel (such as 20CrMnTi) is generally selected to ensure that the gears have sufficient strength and wear resistance. For the manufacturing of blanks, common methods include forging and casting. Forging can improve the internal structure of steel and enhance its mechanical properties; Casting is suitable for production with complex shapes and large batches.

In the tooth profile machining process, the main processes include:

Gear hobbing: Using a gear hobbing machine and a hob, the tooth shape is cut by the generation method. This is an efficient and high-precision processing method suitable for large-scale production. During the gear hobbing process, it is necessary to accurately control the relative motion between the hob and the workpiece, as well as the parameters and installation accuracy of the hob.

Gear shaping: For some special shaped or small-sized steel spur gears, gear shaping technology may be used. The gear shaping machine gradually forms a tooth shape through the reciprocating motion of the gear shaping cutter.

In machining, multiple cutting and measurement adjustments are carried out to ensure the accuracy of tooth profile and the uniformity of tooth pitch. For example, in the machining of steel spur gears used in automotive transmissions, high requirements are placed on the roughness and contact accuracy of the tooth surface, requiring precise process control. After completing the tooth profile machining, heat treatment is usually carried out, such as quenching, tempering, etc., to increase the hardness and toughness of the gear. Subsequently, precision machining processes such as gear grinding may be carried out to further improve the accuracy and surface quality of the tooth surface.

Customizing gears typically involves multiple steps and factors to ensure that the final product meets specific requirements and specifications. The following is the general gear customization process:

Determine requirements: Firstly, it is necessary to clarify key parameters such as the usage scenario, working environment, load requirements, and speed of the gear. These parameters will directly affect the material selection, size design, accuracy requirements, and other aspects of gears.

Material selection: Select suitable gear materials based on the usage environment and requirements. Common gear materials include carbon steel, alloy steel, stainless steel, cast iron, etc. The selection of materials will directly affect the strength, wear resistance, corrosion resistance, and other properties of gears.

Design and drafting: Determine the basic parameters such as tooth number, modulus, and pressure angle of the gear according to the requirements, and use CAD and other drawing software to design and draw the gear. During this process, factors such as gear ratio, transmission efficiency, and noise need to be considered.

Manufacturing and processing: Select appropriate manufacturing and processing methods based on design drawings. Common gear processing methods include gear hobbing, gear shaping, gear milling, etc. Strict control of precision and quality is required during the machining process to ensure the performance and lifespan of gears.

Inspection and testing: After manufacturing is completed, the gears need to be inspected and tested. This includes gear size measurement, accuracy testing, noise testing, etc. Only through strict inspection and testing can the quality and performance of gears meet the requirements.

Customized packaging and shipping: Based on customer needs, customize packaging for gears and arrange for shipping. Before shipping, it is necessary to double check the quality and quantity of the gears to ensure that customers receive satisfactory products.

As custom precision steel spur gear manufacturers, we understand the pivotal role these components play in countless mechanical systems. From automotive transmissions to industrial machinery, the demand for high – quality, precisely engineered spur gears is unwavering, and we take immense pride in our ability to meet and exceed these expectations through our advanced manufacturing processes and unwavering commitment to excellence.

At the core of our operations is a dedication to precision. Steel spur gears require meticulous attention to detail in every aspect of their design and production. The tooth profile, pitch diameter, face width, and overall dimensions must all adhere to extremely tight tolerances to ensure seamless meshing with mating gears and smooth, efficient power transmission. We leverage state – of – the – art computer – aided design (CAD) software to create highly accurate gear models, carefully calculating every parameter to meet our clients’ specific performance requirements. Our computer – aided manufacturing (CAM) systems then translate these designs into precise machining instructions for our advanced CNC machines. With these tools at our disposal, we can produce steel spur gears with an astonishing level of accuracy, ensuring that each gear we manufacture performs flawlessly in its intended application.

Quality is non – negotiable for us. We source only the highest – grade steel materials, carefully selecting alloys that offer the ideal combination of strength, durability, and wear resistance. Our manufacturing facilities are equipped with advanced inspection and testing equipment, allowing us to thoroughly evaluate each gear at every stage of production. We conduct rigorous dimensional inspections, hardness tests, and surface finish measurements to ensure that our gears meet or exceed industry standards. Additionally, we perform comprehensive load – testing and fatigue – testing procedures to verify the gears’ performance under real – world operating conditions. By maintaining such strict quality control measures, we can provide our customers with gears that they can rely on for long – term, trouble – free operation.

Flexibility is another key strength that sets us apart as custom gear manufacturers. We recognize that every client has unique needs, whether it’s a requirement for a specific gear ratio, a non – standard size, or a specialized tooth design. Our team of experienced engineers and technicians is always ready to collaborate closely with our customers, working to understand their specific applications and develop customized gear solutions. We can easily modify our manufacturing processes and tooling to accommodate a wide range of design variations, from small – batch production runs of prototype gears to large – scale orders for mass – produced components. This flexibility allows us to provide our customers with gears that are precisely tailored to their individual requirements, giving them a competitive edge in their respective markets.

Efficiency is also a top priority in our manufacturing operations. We continuously invest in the latest manufacturing technologies and equipment to streamline our production processes and increase productivity. Our CNC machining centers are capable of performing multiple operations, such as milling, hobbing, and shaving, in a single setup, reducing the time spent on repositioning the workpiece and changing tools. This not only speeds up production but also minimizes the potential for errors and improves the overall quality of the gears. Additionally, we have implemented advanced production planning and scheduling systems to optimize our workflow, ensuring that we can meet our customers’ delivery deadlines without compromising on quality.

In conclusion, as custom precision steel spur gear manufacturers, we are committed to providing our customers with the highest – quality gears, tailored to their specific needs, and delivered on time. Our focus on precision, quality, flexibility, and efficiency allows us to stand out in a competitive market and build long – lasting relationships with our clients based on trust and reliability.